State Council nod for nuclear merger soon

The State Council is likely to give its green light for the merger of China's two nuclear giants soon, a move that could lead to sector consolidation and spur more overseas ventures, industry sources said on Thursday.

The long-standing proposal for the merger of China Power Investment Corp and State Nuclear Power Technology Corp, which was first raised in April 2014, got clearance from both companies earlier this year.

Wang Binghua, chairman of SNPTC, said on Tuesday during a nuclear power forum in South Africa that the merged entity would be called State Power Investment Group, with assets exceeding 700 billion yuan ($113 billion) and annual sales of more than 200 billion yuan.

Despite the formal merger proposal, uncertainty persists on how the affiliated units are going to be constituted. Wang, however, reiterated that the merger will lend more impetus to China's exports of third-generation nuclear technology to South Africa.

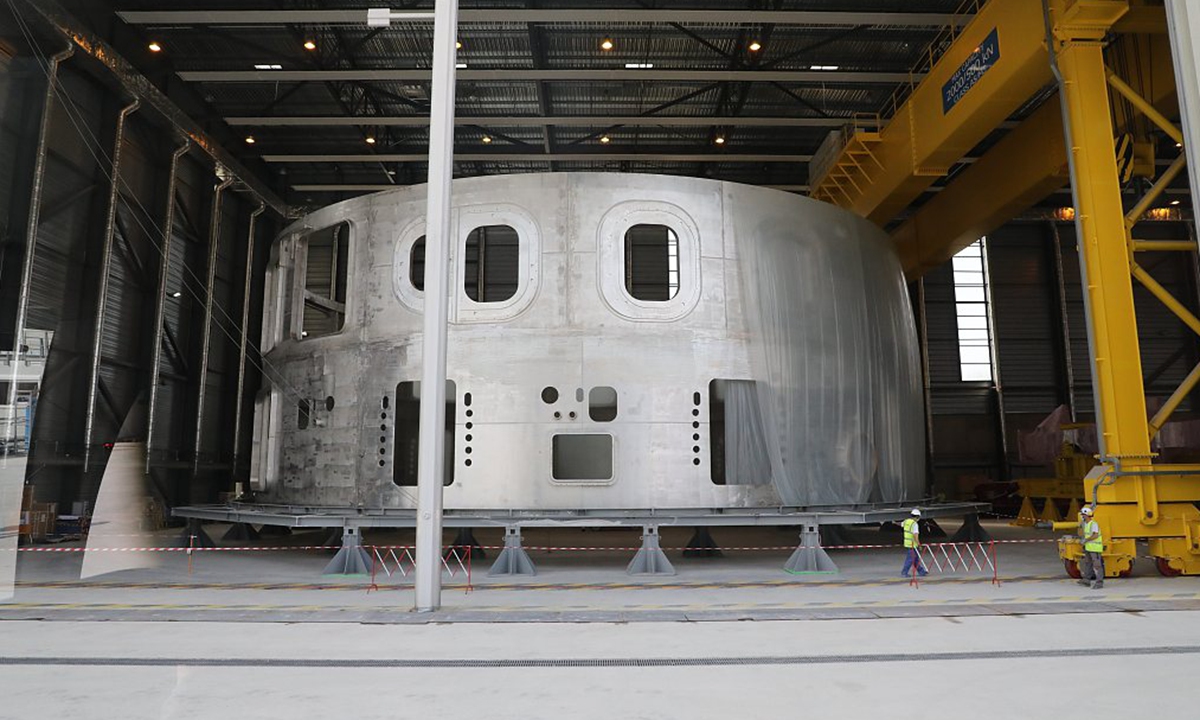

"We are strong in capital management and power generation," Wang said, adding that South Africa was right in opting for the advanced third-generation nuclear technology.

"We are also confident of becoming a faithful and long-standing partner for the nuclear companies in South Africa," he said.

In 2014, Nuclear Energy Corp of South Africa signed a skill development and training agreement with SNPTC to create opportunities for young South Africans to further their studies in nuclear energy and other specialized areas at Chinese universities, with up to 95 percent of funding from Chinese institutions.

Wang said it was a key step toward nuclear power cooperation between China and South Africa.

South Africa, which plans to spend 1 trillion rand ($93 billion) building six nuclear reactors by 2030, has already garnered attention from several leading nuclear firms.

SNPTC faced fierce competition from Rosatom, Russia's State-owned nuclear firm, which was reported earlier to have inked a multi billion dollar deal with South Africa but was subsequently turned down by the South African government.

Experts said the impending merger will give a boost for China's nuclear exports and at the same time kickstart work on several new nuclear reactors.

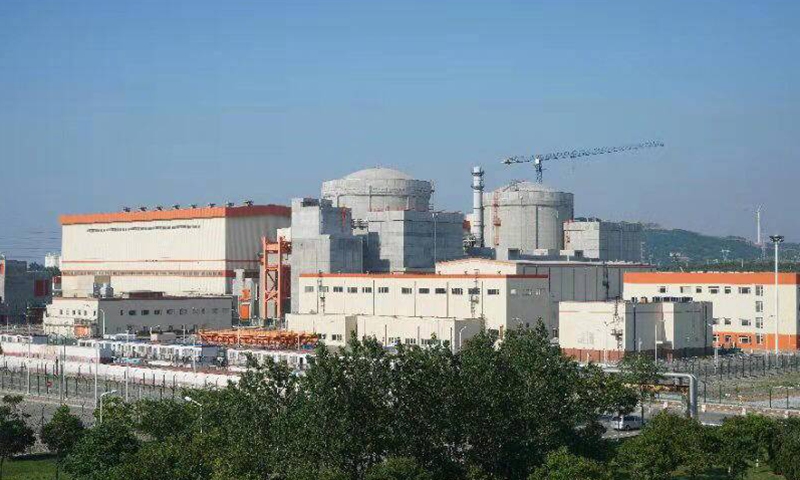

SNPTC was established in 2007 to introduce third-generation nuclear power technology known as AP1000 from the US-based Westinghouse Electric Corp. However, it does not have a license for constructing and operating nuclear power plants.

CPIC possesses one of the only three nuclear operating licenses available in China. The other two companies that have such qualifications are China National Nuclear Corp and China General Nuclear Power Group.

The State Council is likely to give its green light for the merger of China's two nuclear giants soon, a move that could lead to sector consolidation and spur more overseas ventures, industry sources said on Thursday.

The long-standing proposal for the merger of China Power Investment Corp and State Nuclear Power Technology Corp, which was first raised in April 2014, got clearance from both companies earlier this year.

Wang Binghua, chairman of SNPTC, said on Tuesday during a nuclear power forum in South Africa that the merged entity would be called State Power Investment Group, with assets exceeding 700 billion yuan ($113 billion) and annual sales of more than 200 billion yuan.

Despite the formal merger proposal, uncertainty persists on how the affiliated units are going to be constituted. Wang, however, reiterated that the merger will lend more impetus to China's exports of third-generation nuclear technology to South Africa.

"We are strong in capital management and power generation," Wang said, adding that South Africa was right in opting for the advanced third-generation nuclear technology.

"We are also confident of becoming a faithful and long-standing partner for the nuclear companies in South Africa," he said.

In 2014, Nuclear Energy Corp of South Africa signed a skill development and training agreement with SNPTC to create opportunities for young South Africans to further their studies in nuclear energy and other specialized areas at Chinese universities, with up to 95 percent of funding from Chinese institutions.

Wang said it was a key step toward nuclear power cooperation between China and South Africa.

South Africa, which plans to spend 1 trillion rand ($93 billion) building six nuclear reactors by 2030, has already garnered attention from several leading nuclear firms.

SNPTC faced fierce competition from Rosatom, Russia's State-owned nuclear firm, which was reported earlier to have inked a multi billion dollar deal with South Africa but was subsequently turned down by the South African government.

Experts said the impending merger will give a boost for China's nuclear exports and at the same time kickstart work on several new nuclear reactors.

SNPTC was established in 2007 to introduce third-generation nuclear power technology known as AP1000 from the US-based Westinghouse Electric Corp. However, it does not have a license for constructing and operating nuclear power plants.

CPIC possesses one of the only three nuclear operating licenses available in China. The other two companies that have such qualifications are China National Nuclear Corp and China General Nuclear Power Group.